Work Plan

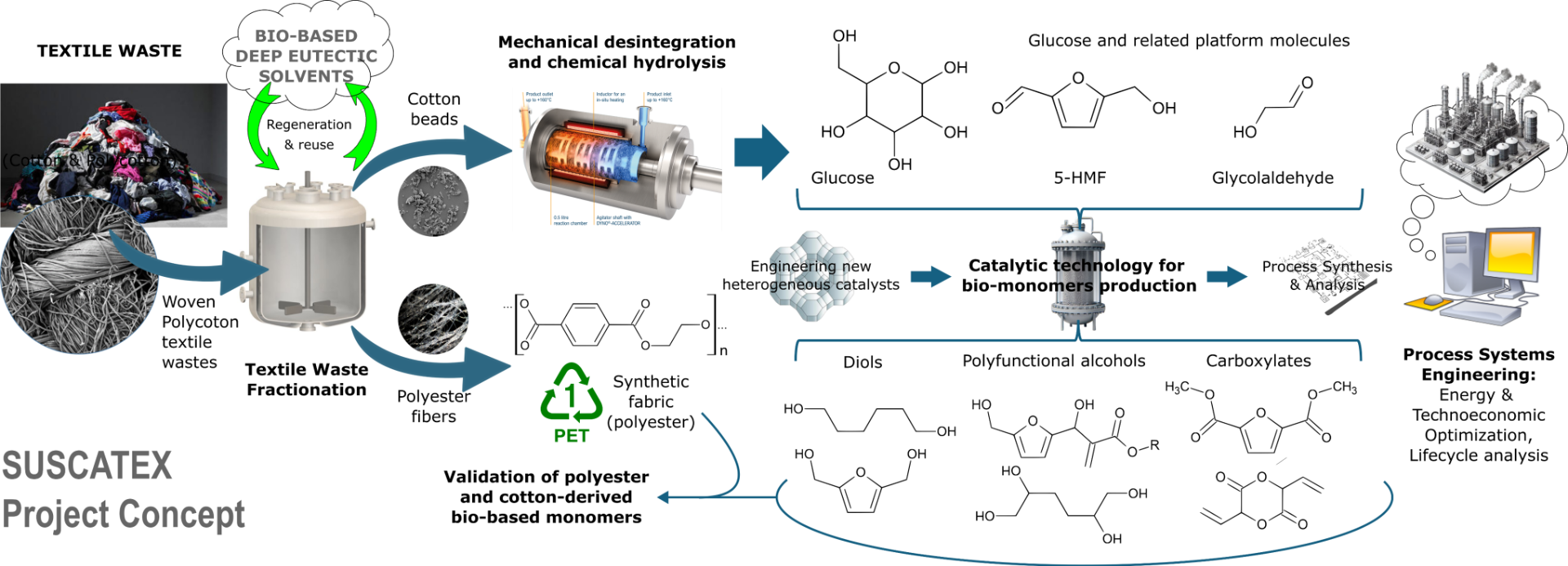

The main objective of SUSCATEX is to design and optimise chemo-catalytic pathways to convert cotton textile waste into valuable chemicals for the synthesis of polymers and other sustainable materials. To achieve this, the work plan is structured in several interconnected phases:

- Fractionation of textile waste using deep eutectic solvents (DES), to separate cellulose and other components in an efficient and environmentally friendly manner.

- Catalytic conversion of cellulose into intermediate compounds such as diols and lactones, using innovative technologies such as mechano-catalysis and selective oxidation.

- Synthesis of polymers from the monomers obtained and modification of recovered synthetic polymers, such as polyester, evaluating properties and potential applications.

- Comprehensive assessment of the sustainability of the processes developed, including Life Cycle Assessment (LCA) and Techno-Economic Analysis (TEA), to ensure environmental and economic viability.

The project is structured into eight work packages (WP) covering all stages of the "textil refinery" concept:

WP1- Fractionation of textile waste

WP2- Synthesis of biomonomers 1: Diols

Design and optimization of processes to separate polyester (PET) and cotton cellulose in polycotton blends using deep eutectic solvents (DES). Includes mechanocatalytic activation of cellulose and its conversion into chemical platforms (glucose, HMF, GA).

Development of bifunctional catalysts to transform glucose and HMF into diols such as isosorbide (ISO), BHMF, BHMTHF, and HDO, which are essential for the production of sustainable polyesters.

WP3- Synthesis of biomonomers 2: Polyfunctional alcohols

WP4- Synthesis of biomonomers 3: Carboxylates

Production of monomers with cross-liking capacity, such as H3O, H4O, and F2OA, using advanced catalytic routes, including rearrangements and cascade reactions.

WP5- New value chains

Obtaining compounds such as FDMC, glycolide, and MVG (and its cyclic dimer) from cotton- derived platforms through oxidation, esterification, and dehydrogenation processes.

WP6- Advanced characterization of catalysts

Validation of monomers in the synthesis of bio-based plymers and upcycling of PET through chemical modification (hydrophilization, insertion of monomers) and photocatalytic processes for depolymerization.

Study of the structure-activity relationship to optimize heterogeneous catalysts, using advanced techniques (XRD, XPS, NMR, DRIFT, SEM/TEM) and analysis of deactivation mechanisms.

WP7- Computational design and sustainability analysis

WP8- Project management and coordination

Aplication of simulation and optimization tools to integrate TEA (techno-economic analysis) and LCA (life cycle analysis) into process design, ensuring technical, economic, and environmental viability.

Consortium coordination, milestone monitoring, data management, internal communication, and organization of meetings and training stays.